Highlights from the event

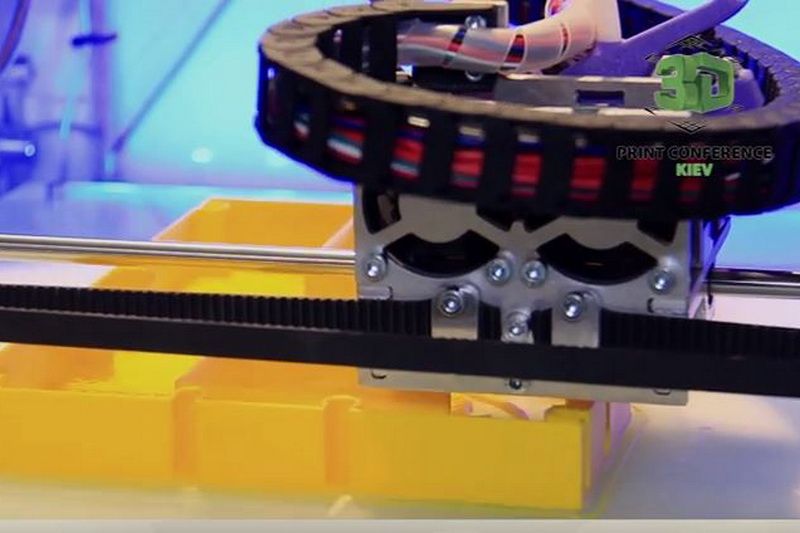

After waiting for quite some time for an interesting industry event related to digital technologies and printing, I finally managed to do it — I’ve attended the 3D Print Conference in Kyiv, held on September, 10th.

Needless to say, it was exciting. Everyone who had a chance to learn more about advanced technologies and innovations knows how inspiring they can be.

The event hosted several zones: an exhibition where technology dealers and service providers presented hardware, software, and printed samples; workshops for everyone interested in hands-on aspects of 3D printing and 3D scanning; a conference hall for presentations; a 3D+Robo Kids zone where the youngest attendees studied the basics of 3D modeling and robo design.

Conference speakers unveiled their personal business stories, experience, and knowledge in order to teach, motivate and engage their audience. The interest was strongly backed by the 4x annual growth of the 3D print market in Ukraine, according to Mares Shamzhi, the conference manager.

The presentation program included 12 talks divided into 3 sessions. Here are few of the things said that, to my opinion, were really inspiring and motivating:

* * *

Darya Kireeva from Materialise, a Belgium-based company that has been playing a large role in additive manufacturing for the past 25 years, was the first to describe the current state and emerging trends in 3D printing technologies.

From selective laser sintering (SLS), its widest range of materials covering wood and titan, to stereolithography (SLA) offering largest models and supporting transparent resin, to fused deposition modeling (FDM), the most well-known and popular 3D printing method, every technology has its certain limitations and strong points taken into account when you choose a 3D system for your project.

The presentation covered interesting case studies and models currently manufactured by Materialise from different materials. Among them, Darya mentioned a mind-blowing Spider Dress 2.0 equipped with an Intel Edison chip that reads biosignals to defend the wearer’s personal space.

Additional questions showed that people are not yet fully aware of functional potential available with new technologies. Somebody asked what it would cost to produce an Ikea-like lamp using 3D printing.

Obviously, the lamp will be unique. This approach, however, fails to exploit the inherent advantages of the process not limited to ‘one of its kind.’ To take full advantage of additive manufacturing, you need to rethink production design making it more cost-effective and enhancing performance parameters. The new geometric freedom is another unique advantage of 3D printing.

* * *

The largest 3D printers installed at Materialise can produce components 2 meters in height. But if you need an entry-level home 3D printer you can as well make your own customized system. Alexander Novakovskyy from 3DP company says a 3D printer cobbled together from whatever parts you can find may cost you only $500 if you know where to buy the components. From choosing a RepRap or RepStrap strategy for your 3D printer to finding the best-suited print head, every step is achievable. But get ready to be on short terms with G-code, an ‘official language’ of 3D printers.

* * *

Eugene Kozhukhovskyy, Managing Partner of SmartPrint, thinks that Ukraine has a good global market potential for 3D printing with the SMB sector entering massive technology adaptation.

For Ukraine and former CIS countries, spare parts are the most demanded 3D components now. But your customers may be located globally if you find the right way to reach out to them.

According to Kozhukhovskyy, an average price claimed by print services providers at 3D Hubs (local 3D printing services and 3D printing) is 0.98 euro per 1 gram for Europe and only 0.19 euro per 1 gram for Ukraine.

At present, twenty 3D printers are available in Kyiv via 3D Hubs service (30 in Ukraine). However, if you plan to enter the segment, do not sell you services but rather try to solve your clients’ problems, he says.

In September, SmartPrint initiated a charity project offering free 3D printed prosthetics for children without arms and/or hands. The feedback shows that the interest is huge, so the company is open for charity cooperation with other 3D print service providers.

* * *

Medical startup ARanEd founded by Andrey Maranov, a medical student from Kyiv, suggests a holistic approach to human skeleton research using 3D printing and augmented reality.

Project participants scan human bones to make accurate 3D printed copies as real human samples are prohibited for medical students now. They claim that their representations are attractively priced and their quality meets strict demands of both students and doctors (the skeleton will cost you about $400).

Maranov’s second project is a mobile application to scan and to visualize the real structure of human body with the help of AU technologies.

In 2015, the startup has already become a winner of PioneersKyiv festival, a part of Europe’s major startup and investor conference, and was presented successfully at Thiel Summit in Saint Francisco, June 2015.

* * *

Alexander Nam, Head of Software & Hardware Development at EnvisionTEC, told about 3D printing of scaffolds for bioengineering enabling the production of functional living implants out of cells obtained from cell culture.

In contrast to conventional rapid prototyping systems, mainly focused on melt processing, the 3D-Bioplotter by EnvisionTEC can apply a much larger variety of synthetic as well as natural materials, including aqueous solutions and pastes, to fabricate scaffolds for tissue engineering.

Today, dental clinics and laboratories are already facing a digital upheaval. Bone reconstruction technologies with the help of three-dimensional structures are being developed. The next step will be organ transplantation.

Only in the US, an average of 22 people dies each day waiting for transplants that can’t take place because of the shortage of donated organs. The gap between the demand and available organs continues to widen. 3D printed kidneys could potentially save thousands of lives.

It’s still a long way to fully functional tissue engineering. According to Alexander, one may expect a 3D printed liver in about 15 years and a 3D printed heart in 25 years.