Highlights from the event

Staying on track with my professional development, I visited the 3D Print Conference (Kyiv, Ukraine, September 16).

Last time I came to a local 3D Print Confrerence conference was a year ago. And I should say that by now I have learnt a lot more about the technologies, innovations and trends (thanks, the University of Illinois!). So, Ukrainian projects, start-ups and the local market were of main interest for me.

Once more, the venue consisted of four main zones. Apart from the exhibition, there was a 3D printing and 3D scanning workshop. The conference hall hosted the presentations, and my child spent time in the kids’ workshop zone.

The organisers assure that the third Conference welcomed more guests and exhibiting companies. But it seems to me that by now it somewhat lacks the level and drive it deserves. I hope we will see alternatives and new formats offered by Ukrainian and European expo companies.

This year, the presentation program included 10 talks with some last-minute changes. Some of them were quite inspiring.

3D Printing for Development in Ukraine

Brennan Purtzer, the Founder of Blue Continent Eco-Trade Alliance, is currently volunteering for the US Peace Corps in Ivano-Frankivsk, Western Ukraine.

To his opinion, 3D printing for development can have a much more important impact on society that creating art or jewellery pieces. 3D technologies are already being used for the development of Africa, Philippines, Pakistan, etc.

Brennan relies on his experiences with Micronesia, one of the most isolated regions. The supply chain there is long, slow, and expensive. And the national GPD depends on import to a great extent.

Here 3D printing could shorten the supply chain offering limited on-island production. Among other benefit are better-paying jobs, technical training, better import and export balance. Moreover, the reduced shipping volume means positive environmental impact. With 3D printing, small communities can use recycled plastics to build new items they need.

According to Brennan Purtzer, the same process could be used in Ukraine. But the best solutions for Ukraine are the ones we have yet to invent to solve specific, local issues.

Brennan is planning to open a 3D print learning centre in Kalush near Ivano-Frankivsk. A nation-wide network might follow later.

Printed houses: autonomous and self-learning

Maxim Gerbut, founder and CEO of Ukrainian PassivDom, presented an interesting concept of a printed modular PassivHause.

The startup claims to have created the world’s warmest passive houses. The structure is carbon and glass fibre combined with patented warm windows. An extremely low heat loss makes self-sufficiency easy and cost-effective to implement.

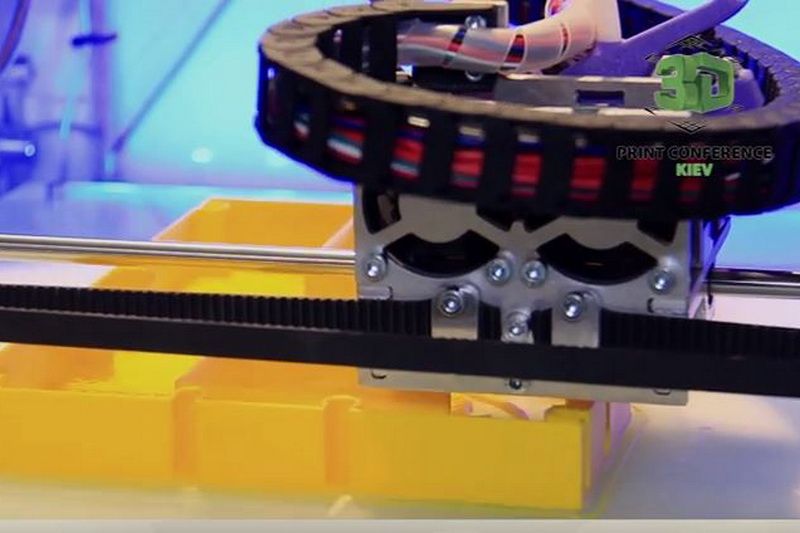

Basic structures, including walls, roofing, and basement platform, are produced with 3D printing by “7D” robotic arms. The dimensions of a basic transportable PassivDom module are 4 m x 9 m (12 tonnes). If case you need a larger building, you are free to combine two modules.

Unlike concrete 3D printing, the original houses are promising full off-grid autonomy. It seems like you do not need any traditional heating system even for cold regions. The thermal characteristics allow using 20 times less energy than usual. Obviously, they outperform the new energy efficiency standards that come into effect in 2030 in the USA and Europe.

The modular houses use solar panels and batteries to produce energy and store it. Even with heavy clouding, the energy supply is enough to keep self-efficiency for up to two weeks. All house appliances are integrated into the Internet of Things. A self-learning system monitors the quality of air inside. Actually, you can control the house from anywhere with the help of your smartphone.

Made in Ukraine: high-quality 3D printing filament

Oleg Kireev, a representative of Extrusion in Motion, told about methods of quality control and testing of ABS and PLA filaments.

A pioneer Ukrainian manufacturer of 3D filament produces excellent-quality materials for 3D printers. Launched in 2016, the manufacturing site is equipped with advanced quality measurement systems and production lines. For their 3D filament, the company exports 100% fresh raw materials from North America.

EIM has already tested its 3D filament in German laboratories. The results were good enough to launch the export of the product made in Ukraine to the market of Germany. Currently, EIM is undergoing certification procedures to comply with the TÜV and European RoHS directive 2002/95/EC.

The R&D department continues to develop new materials in close cooperation with leading suppliers of 3D printers and 3D scanners. Wood, metal, carbon filaments, Flex, and rubber are currently at work. ‘Run by engineers for engineers’, EIM is also planning to offer 3D printing and 3D scanning services, measurement systems, industrial 3D printing technologies, and recycling.

* * *

Just after the 3D Print Conference in Kyiv, Kwambio announced the launch of its first European 3D printing factory based in Ukraine. The company is ready to compete with Materialise and Shapeways using its own ceramic powder (80 colours!).

“Our goal is to offer high-quality products at affordable prices. Thanks to our incredible team and a perfect eco-friendly location in Ukraine, Kwambio cuts prices and lead time in half,” said Vlad Usov, CEO and co-founder of Kwambio.

Kwambio processes online and third-party orders accepting all kinds of sketches. Your product will be ready from scratch in just two weeks. The price is $0.07 for one cubic centimetre.