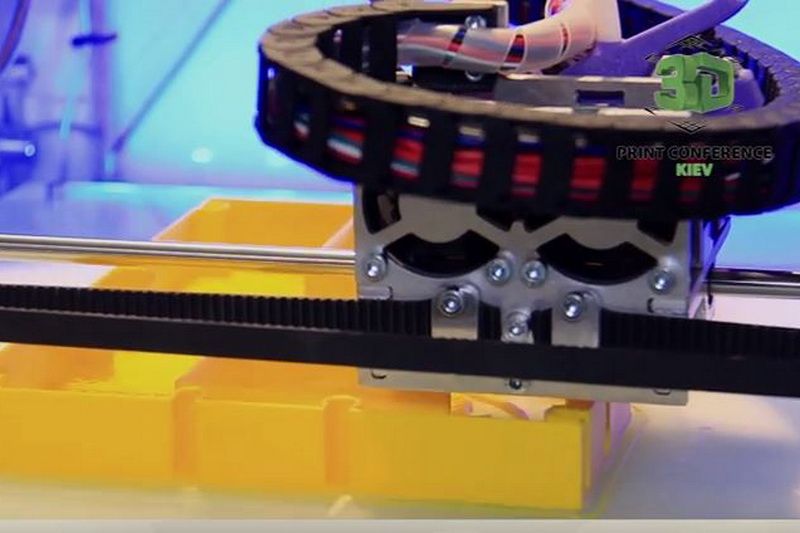

3D Print Conference Kyiv, 2016

Staying on track with my professional development, I visited the 3D Print Conference (Kyiv, Ukraine, September 16). Last time I came to this conference was a year ago. And I should say that by now I have learnt a lot more about the technologies, innovations and trends (thanks, the University of Illinois!). So, Ukrainian projects, start-ups and the local market were of main interest for me.